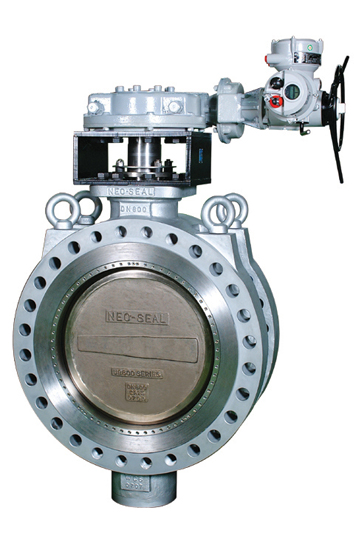

Triple Offset Valve (Metal & Graphite Seat / Solid Metal Seat)

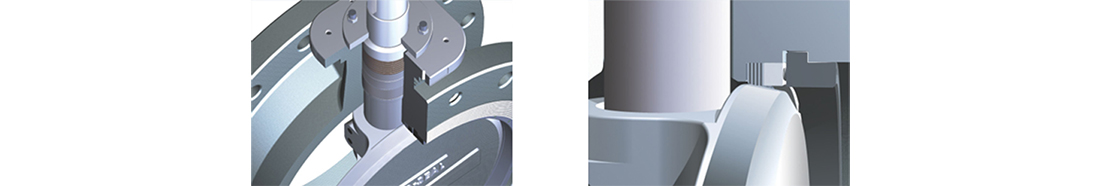

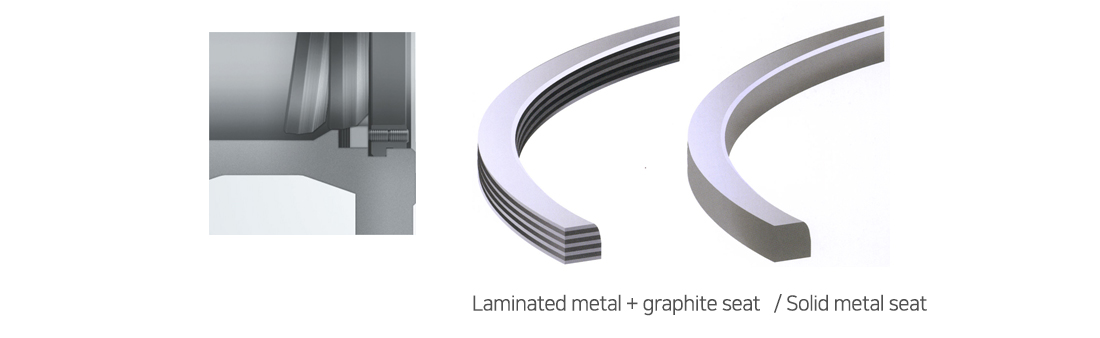

When Triple offset Design is introduced to the market, Triple Offset Design (TOD) overcomed the limitations of Double Offset Design. Double Offset Design is prone to excessive wear from friction and abrasion between sealing components. To eliminate problems, TOD features a special sealing mechanism that consists of an inclined conical disc and a laminated seat. The unique characteristics of TOD are low torque operation, broad sealing width and bi-directional tight shut-off.

| Design | ASME B16.34 / API std 609 Category B |

|---|---|

| Rating | ASME Cl. 150,300,600,900,1500 PN10, 16, 20, 25, 40, 64, 100 |

| Size | DN80(3“) to DN2000 (80”) |

| Connection Type | Double Flanged / Lugged & Wafer / Butt Weld End |

| Temperature Range | -50℃ ~450℃ |

| Main Material |

Body : WCB, CF8, CF8M etc. Disc : CF8, CF8M (With Stellite or ENP) etc. Shaft : 17-4PH, 316SS etc. Seat : 316ss + Graphite etc. |

| Operator |

Manual Worm Gear Pneumatic Actuator Electric Actuator |

| Application |

General Industrial & Petro Chemical Plant Oil Refinery / Production Gas / Pulp / Paper Industry Steel and Iron Mill Shipbuilding District Heating / Water and Sewage Combined / Nuclear power plant Hydrocarbon storage and Transportation Sugar Industry Other Plant engineering |

| Option |

Stellite or ENP on Disc Anti-static device Manual operator with Locking device Bonnet / Stem extension Heating jacket ISO 15848 Fugitive Emission packing NACE MR 0103 / 0175 |

Designed to ensure fire safety.