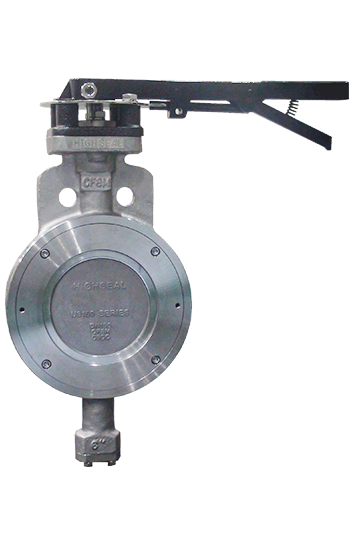

Soft Seat Valve

Soft Seat designed for critical requirements has proven its reliability and efficiency in a wide rage of application for more than 25 years.

Mechanism with and eccentric structure minimizes an on-off torque at high pressure, providing tight shut-off.

Carbon steel and stainless steel are standard materials for body and trim with a Teflon seat.

Other special materials or particular treatment on trim and body are available as per the application and service.

| Design | API std 609 Category B |

|---|---|

| Rating | ASME Cl. 150 / Cl. 300 / Cl. 600 PN 10, 16, 25, 40, 60, 64 JIS 10K, 16K, 20K |

| Size | DN50(2”) to DN1800 (72”) |

| Connection Type | Double Flanged / Lugged & Wafer |

| Temperature Range | -40℃ to 250℃ |

| Main Material | Body : WCB, CF8, CF8M etc. Disc : CF8, CF8M etc. Shaft : 17-4PH, 316SS etc. Seat : PTFE, RPTFE, CTFE, UHMW-PE etc. |

| Operator |

Manual Hand lever / Manual Worm Gear Pneumatic Actuator Electric Actuator |

| Application |

General & Petro Chemical Oil Refinery / Production Steel and Iron Mill Shipbuilding Combined / nuclear power plant Water / Sewage Other Plant engineering |

| Option |

Anti-static device Manual operator with Locking device Bonnet / Stem extension Internal Teflon / Velzona coating Low temperature design ISO 15848 Fugitive Emission packing NACE MR 0103 / 0175 |